QHSE Management in Data Centre Construction Projects

QHSE Management in Data Centre Construction Projects

Quality, Health, Safety, and Environmental Protocols for Mission-Critical Infrastructure

The construction of hyperscale data centres presents unique QHSE challenges that extend far beyond traditional commercial construction projects. The precision required for mission-critical infrastructure, the complexity of advanced mechanical and electrical systems, and the stringent environmental standards demanded by modern sustainability requirements create QHSE management challenges that require specialist expertise and systematic approaches.

Traditional construction QHSE methodologies—designed for conventional building projects—prove inadequate when confronted with the technical precision, safety complexity, and environmental sensitivity of hyperscale data centre construction. These facilities require QHSE management systems that address the specific risks, quality requirements, and environmental considerations inherent in mission-critical digital infrastructure development.

At AuditCo, our partnership with Qcloud has enhanced our capability to deliver comprehensive QHSE management services that address the unique requirements of hyperscale data centre construction. This collaboration combines our established expertise in systematic QHSE protocols with Qcloud’s deep understanding of hyperscale construction challenges and performance standards.

The Strategic Framework of Integrated QHSE Management

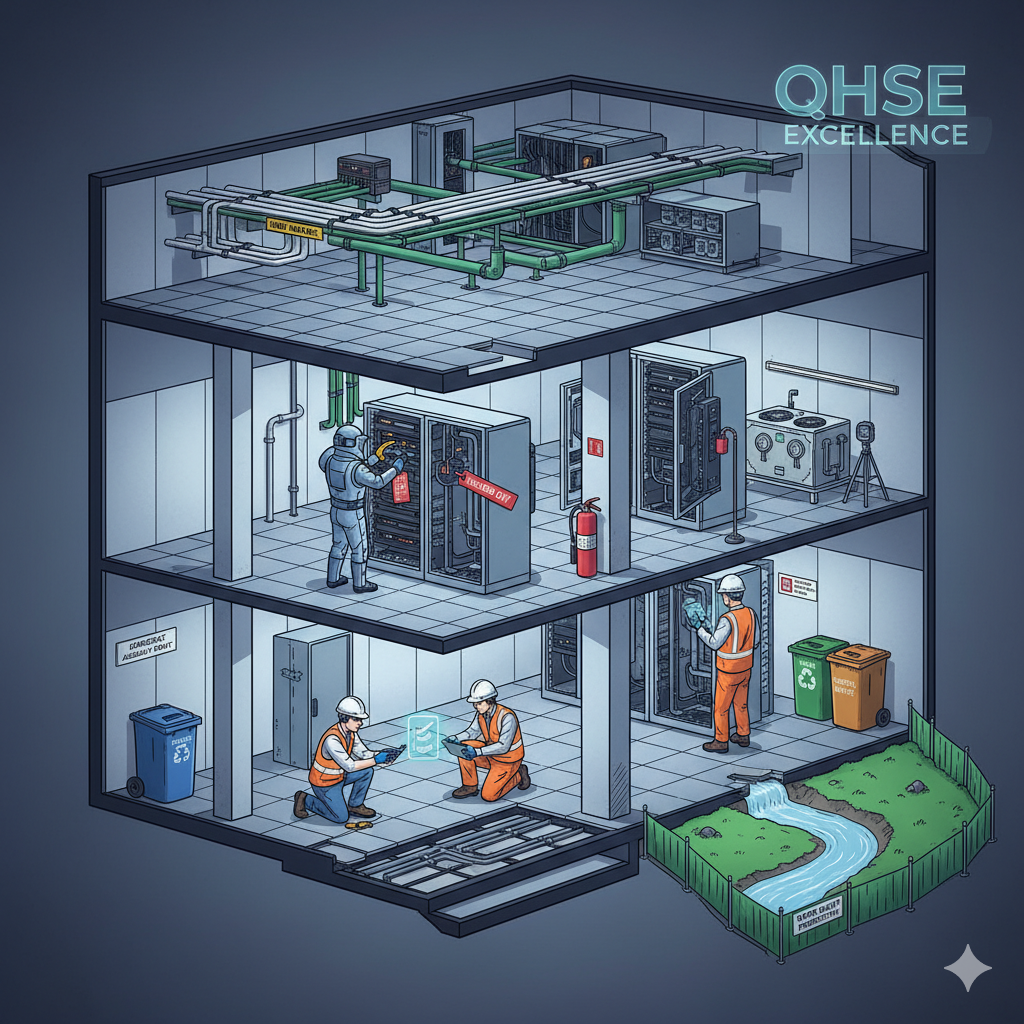

Quality, Health, Safety, and Environmental management represents an integrated discipline where each element influences and supports the others throughout construction processes. Effective QHSE management requires systematic approaches that address these interconnected elements cohesively rather than managing them as separate disciplines that may conflict or create inefficiencies.

Quality management in data centre construction encompasses the precision manufacturing tolerances, installation accuracy, and performance verification required for mission-critical operations. Quality protocols must address the exceptional precision required for raised floor systems, the accuracy demands of power distribution installations, and the environmental tolerances required for cooling system commissioning.

Health and safety management addresses the substantial risks associated with electrical systems operating at high voltages, mechanical equipment with significant stored energy, and construction activities in confined spaces with complex utility systems. Safety protocols must account for arc flash hazards, confined space entry, and the coordination challenges of multiple specialty contractors working simultaneously.

Environmental management encompasses both construction impact mitigation and the sustainability performance required for modern data centre operations. Environmental protocols must address construction waste management, air quality protection during construction, and the integration of sustainability systems that will influence long-term facility environmental performance.

The integration of QHSE management creates synergies where quality improvements enhance safety performance, safety protocols support environmental protection, and environmental management contributes to overall construction quality. Systematic integration prevents conflicts between QHSE objectives whilst optimising overall project performance.

Quality Management Systems and Construction Excellence

Construction quality management for data centre projects requires precision standards that exceed those of conventional construction, where tolerances measured in millimetres can influence long-term facility performance and reliability. Quality management systems must address both the precision installation requirements and the comprehensive verification procedures required for mission-critical infrastructure.

ISO 9001 quality management system principles provide the foundation for systematic quality control, but data centre construction requires enhanced procedures that address the specific precision and performance requirements of hyperscale facilities. Enhanced quality systems include detailed work instructions, comprehensive inspection procedures, and rigorous documentation requirements.

Material quality control procedures ensure that construction materials meet the exceptional standards required for mission-critical applications. Material control includes incoming inspection procedures, storage requirements, and handling protocols that prevent degradation or contamination that could compromise installation quality or long-term performance.

Installation quality verification requires comprehensive inspection procedures that confirm construction work meets design specifications and installation standards throughout construction processes. Quality verification includes dimensional accuracy confirmation, installation integrity verification, and performance testing that ensures construction quality.

Workmanship standards for data centre construction must address the precision installation requirements, aesthetic standards, and long-term durability requirements that influence both immediate performance and lifecycle maintenance requirements. Workmanship standards include detailed specifications, training requirements, and inspection procedures.

Quality assurance documentation provides comprehensive records of construction quality throughout project delivery, creating the documentation required for warranty compliance, commissioning support, and ongoing facility management. Documentation includes inspection records, test results, and corrective action reports that demonstrate quality achievement.

Health and Safety Protocols for High-Risk Construction Activities

Electrical safety management represents perhaps the most critical aspect of data centre construction safety, where high-voltage electrical systems create substantial arc flash hazards that require comprehensive safety protocols, specialised personal protective equipment, and rigorous safety procedures throughout construction and commissioning activities.

Arc flash risk assessment and mitigation procedures are essential for data centre construction where electrical systems operate at voltage levels that create substantial injury risks. Arc flash protocols include hazard analysis, appropriate PPE selection, safe work procedures, and emergency response planning that protects personnel throughout electrical construction activities.

Confined space safety management addresses the substantial risks associated with electrical vault construction, utility tunnel work, and mechanical room activities where limited access and emergency egress create significant safety challenges. Confined space protocols include atmospheric testing, emergency rescue procedures, and communication requirements.

Mechanical system safety addresses the risks associated with heavy equipment installation, pressure system testing, and rotating machinery commissioning that create injury risks throughout construction processes. Mechanical safety protocols include lifting procedures, lockout/tagout requirements, and equipment commissioning safety procedures.

Chemical hazard management addresses the risks associated with refrigerants, cleaning solvents, and other hazardous materials used throughout data centre construction. Chemical safety protocols include material safety data sheet management, exposure prevention, and emergency response procedures for chemical incidents.

Construction site safety coordination becomes particularly complex for data centre projects where multiple specialty contractors must work simultaneously in confined spaces with complex utility systems. Safety coordination includes detailed safety planning, contractor safety qualification, and ongoing safety performance monitoring throughout construction.

Emergency response planning for data centre construction must address the unique risks and response challenges associated with electrical emergencies, chemical incidents, and medical emergencies in complex construction environments. Emergency planning includes response procedures, evacuation routes, and coordination with local emergency services.

Environmental Management and Sustainability Integration

Construction environmental management addresses both temporary construction impacts and the long-term environmental performance of completed facilities. Environmental protocols must minimise construction impact whilst ensuring that sustainability systems are installed correctly and will deliver designed environmental performance throughout facility operations.

Air quality management during construction prevents dust generation, controls emissions from construction equipment, and protects indoor air quality in adjacent occupied spaces. Air quality protocols include dust control measures, equipment emission controls, and indoor air protection procedures during construction activities.

Waste management systems address both construction waste reduction and proper disposal of construction materials, packaging waste, and hazardous materials used during construction. Waste management includes waste reduction strategies, recycling procedures, and hazardous waste disposal protocols that minimise environmental impact.

Water quality protection prevents contamination of groundwater and surface water from construction activities, material storage, and temporary facilities. Water protection includes erosion control, stormwater management, and spill prevention procedures that protect local water resources throughout construction.

Noise control management addresses community impact from construction activities whilst maintaining productivity requirements and construction schedules. Noise control includes equipment selection, work hour restrictions, and community communication that minimises noise impact whilst supporting project delivery.

Sustainability system installation quality affects long-term facility environmental performance, making construction quality essential for achieving designed sustainability outcomes. Sustainability installation includes energy-efficient system commissioning, renewable energy system installation, and environmental monitoring system deployment.

Environmental compliance verification ensures that construction activities and completed facilities meet applicable environmental regulations, permit requirements, and sustainability certifications. Compliance verification includes regulatory compliance confirmation, permit condition fulfilment, and certification requirement validation.

Risk Assessment and Hazard Management

Construction risk assessment for data centre projects must address the unique hazards associated with high-voltage electrical systems, complex mechanical equipment, and the precision requirements of mission-critical construction. Risk assessment includes hazard identification, risk evaluation, and mitigation strategy development that addresses project-specific risks.

Electrical hazard assessment addresses arc flash risks, shock hazards, and electrical fire risks associated with power distribution system construction and commissioning. Electrical hazard assessment includes energy calculations, PPE requirements, and safe work procedure development that protects personnel throughout electrical construction.

Mechanical hazard assessment addresses risks associated with heavy equipment installation, pressure system testing, and rotating machinery commissioning. Mechanical hazard assessment includes lifting analysis, pressure testing procedures, and machinery safety verification that ensures safe construction practices.

Chemical hazard assessment addresses exposure risks from refrigerants, cleaning solvents, and other hazardous materials used throughout construction. Chemical assessment includes exposure evaluation, control measure selection, and emergency response planning that protects personnel and environmental resources.

Ergonomic hazard assessment addresses physical stress risks associated with repetitive installation activities, awkward working positions, and material handling requirements common in data centre construction. Ergonomic assessment includes job analysis, control measure implementation, and training programs that prevent musculoskeletal injuries.

Environmental hazard assessment addresses risks to local ecosystems, water resources, and air quality from construction activities. Environmental assessment includes impact evaluation, control measure selection, and monitoring procedures that prevent environmental damage during construction.

Training and Competency Management

QHSE training programs for data centre construction must address the specific knowledge and skills required for safe, quality construction of mission-critical facilities. Training programs include general QHSE awareness, project-specific hazard training, and specialty skill development that ensures construction team competency.

Safety training requirements include electrical safety awareness, arc flash protection, confined space entry, and emergency response procedures specific to data centre construction environments. Safety training includes classroom instruction, hands-on demonstration, and competency verification that ensures safe work practices.

Quality training addresses the precision installation requirements, inspection procedures, and documentation standards required for mission-critical construction quality. Quality training includes technical instruction, quality procedure training, and inspection technique development that supports construction quality achievement.

Environmental training addresses construction impact prevention, sustainability system installation, and environmental compliance requirements throughout construction processes. Environmental training includes impact awareness, control procedure training, and compliance verification that supports environmental protection.

Competency verification procedures ensure that construction personnel demonstrate the knowledge and skills required for safe, quality work on data centre construction projects. Competency verification includes knowledge testing, skill demonstration, and ongoing performance monitoring that maintains construction team capability.

Ongoing training programs address changing construction techniques, evolving safety requirements, and emerging environmental standards that influence data centre construction practices. Ongoing training includes update briefings, refresher training, and new technology instruction that maintains current competency.

Incident Management and Continuous Improvement

Incident reporting systems provide comprehensive documentation of safety incidents, quality issues, and environmental events that occur during construction, creating data for analysis and improvement of QHSE performance. Incident reporting includes immediate notification, detailed investigation, and corrective action development.

Root cause analysis procedures ensure that incidents are investigated systematically to identify underlying causes and develop effective corrective actions that prevent recurrence. Root cause analysis includes systematic investigation techniques, cause identification, and corrective action verification that addresses fundamental issues.

Corrective action management ensures that identified QHSE deficiencies are addressed systematically whilst maintaining construction schedules and quality objectives. Corrective action management includes action plan development, implementation tracking, and effectiveness verification that ensures problem resolution.

Performance monitoring systems provide ongoing assessment of QHSE performance throughout construction, enabling proactive management and continuous improvement of construction practices. Performance monitoring includes metric development, data collection, and trend analysis that supports QHSE optimisation.

Audit and inspection programs provide independent verification of QHSE performance whilst identifying improvement opportunities and compliance gaps. Audit programs include internal audits, third-party assessments, and regulatory inspections that verify QHSE effectiveness.

Lessons learned documentation captures QHSE insights and improvement opportunities from completed projects, supporting continuous improvement and knowledge sharing across future data centre construction projects. Lessons learned include best practice identification, improvement recommendations, and knowledge preservation.

Technology Integration and Digital QHSE Management

Digital QHSE management systems enable real-time monitoring of construction safety, quality verification, and environmental performance whilst providing comprehensive documentation and analysis capabilities. Digital systems include mobile reporting, automated monitoring, and integrated analysis that enhance QHSE effectiveness.

Mobile technology applications enable field personnel to report QHSE observations, access procedures, and communicate requirements instantly whilst maintaining comprehensive documentation. Mobile applications include incident reporting, inspection checklists, and procedure access that support field QHSE management.

Automated monitoring systems provide continuous surveillance of construction environments, enabling immediate response to safety hazards, quality issues, and environmental problems. Automated monitoring includes sensor networks, alert systems, and data logging that enhance QHSE awareness.

Data analytics capabilities enable comprehensive analysis of QHSE performance trends, predictive identification of potential problems, and optimisation of QHSE management strategies. Analytics capabilities include trend analysis, predictive modeling, and performance optimisation that support continuous QHSE improvement.

Integration platforms connect QHSE management systems with construction planning, quality management, and project management systems that enable coordinated project delivery whilst maintaining QHSE excellence. Integration platforms provide unified visibility and coordinated control of construction activities.

Regulatory Compliance and Standards Integration

QHSE regulatory compliance for data centre construction encompasses building codes, safety regulations, environmental requirements, and industry standards that influence construction practices and facility approval. Compliance management includes requirement identification, implementation planning, and verification procedures.

Building code compliance addresses structural requirements, fire protection standards, and accessibility requirements specific to data centre construction. Code compliance includes design verification, construction inspection, and approval documentation that ensures regulatory acceptance.

Safety regulation compliance includes occupational safety requirements, electrical safety standards, and emergency response regulations that protect construction personnel. Safety compliance includes procedure development, training requirements, and inspection verification that ensures regulatory adherence.

Environmental regulation compliance addresses air quality standards, waste disposal requirements, and water protection regulations that influence construction practices. Environmental compliance includes permit management, monitoring requirements, and reporting obligations that ensure environmental protection.

Industry standard compliance includes quality management standards, safety management systems, and environmental management standards that demonstrate construction excellence. Standard compliance includes certification maintenance, audit requirements, and continuous improvement that supports industry recognition.

The Integrated Approach: Delivering QHSE Excellence Through Partnership

Our partnership with Qcloud enables AuditCo to deliver comprehensive QHSE management services that address the unique requirements of hyperscale data centre construction whilst maintaining the integration and systematic approaches required for construction excellence. This collaboration combines our established expertise in QHSE management with deep understanding of hyperscale construction challenges.

The integrated approach encompasses comprehensive QHSE planning, systematic implementation, and continuous monitoring that ensures construction projects achieve quality objectives whilst maintaining safety performance and environmental protection. This methodology prevents the QHSE issues that can affect construction projects with inadequate management systems.

Quality assurance services provide systematic verification of construction quality whilst identifying improvement opportunities and ensuring compliance with design specifications. Quality services include inspection programs, testing verification, and documentation management that supports construction quality achievement.

Safety management services provide comprehensive safety program development, hazard assessment, and incident management that protects construction personnel whilst maintaining productivity objectives. Safety services include safety planning, training programs, and performance monitoring that ensures safe construction practices.

Environmental management services provide comprehensive environmental planning, impact assessment, and compliance verification that protects environmental resources whilst supporting sustainability objectives. Environmental services include impact prevention, monitoring programs, and compliance documentation that ensures environmental protection.

Training and development services ensure that construction teams receive comprehensive QHSE preparation whilst maintaining competency throughout construction processes. Training services include program development, competency verification, and ongoing education that supports QHSE excellence.

Conclusion: QHSE Excellence for Construction Success

QHSE management represents an essential foundation for successful hyperscale data centre construction, where quality precision, safety performance, and environmental protection directly influence both construction success and long-term facility performance. Comprehensive QHSE management ensures that construction projects achieve their objectives whilst protecting personnel and environmental resources.

Our partnership with Qcloud enables AuditCo to deliver the comprehensive QHSE management services that hyperscale construction projects require for successful delivery whilst maintaining the highest standards of quality, safety, and environmental protection. By combining systematic QHSE methodologies with deep construction expertise, we help clients achieve construction excellence.

The investment in professional QHSE management services represents essential preparation for successful construction delivery whilst establishing the foundation for long-term facility success. For hyperscale operators seeking to ensure that construction projects deliver optimal results whilst maintaining exemplary QHSE performance, comprehensive QHSE management provides the systematic foundation for achieving these objectives.

AuditCo provides comprehensive audit, inspection, and compliance services for digital infrastructure projects worldwide. Our partnership with Qcloud enables integrated design-build-comply solutions that deliver QHSE excellence throughout hyperscale data centre construction. For more information about our QHSE management services, please contact our team at info@auditco.com.au