Liquid Cooling Systems: Design, Installation and Compliance

Emerging Cooling Technologies and Regulatory Requirements for High-Density Computing

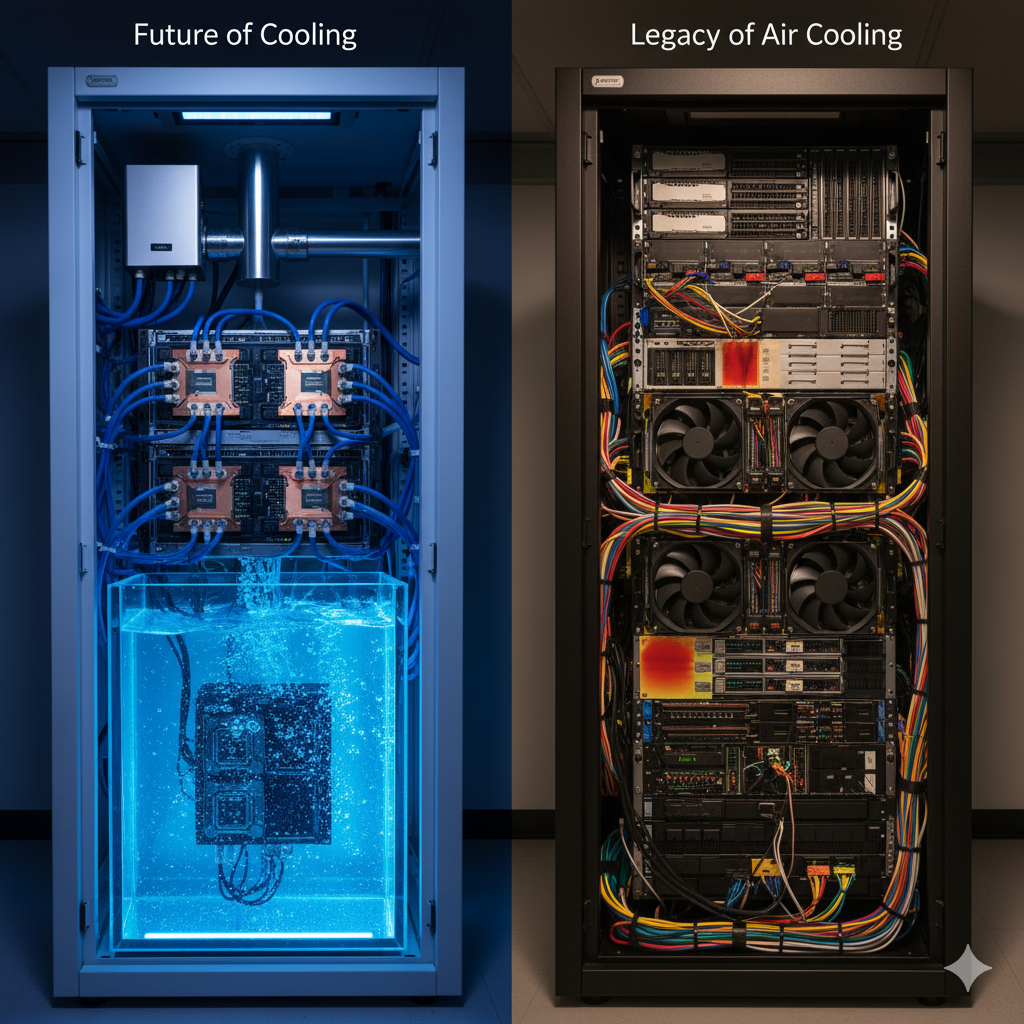

The exponential growth of computational density driven by artificial intelligence workloads, high-performance computing applications, and advanced graphics processing has created thermal management challenges that traditional air-based cooling systems cannot address economically or physically. Rack power densities exceeding 30 kilowatts per rack—with individual server configurations approaching 100 kilowatts—demand liquid cooling solutions that can remove heat efficiently whilst maintaining the precision environmental control required for mission-critical computing operations.

Traditional air cooling approaches reach fundamental physical limitations at high power densities, where airflow volumes required for adequate heat removal create acoustic challenges, energy consumption concerns, and spatial constraints that render air cooling impractical. Liquid cooling technologies provide thermal management capabilities that enable higher computational densities whilst reducing energy consumption and improving operational efficiency compared to equivalent air cooling installations.

At AuditCo, our partnership with Qcloud has enhanced our capability to deliver comprehensive liquid cooling design, installation, and compliance services that address the emerging requirements of high-density computing infrastructure. This collaboration combines our established expertise in regulatory compliance and quality assurance with Qcloud’s understanding of advanced cooling technologies and implementation methodologies.

The Technical Foundation of Liquid Cooling Technologies

Liquid cooling encompasses diverse technological approaches that differ fundamentally in implementation methodology, thermal performance characteristics, and operational requirements. Understanding these technology variations proves essential for appropriate system selection, effective design development, and successful implementation that meets both performance and compliance requirements.

Direct-to-chip cooling represents the most thermally efficient liquid cooling approach, where coolant circulates through cold plates mounted directly onto heat-generating components such as processors and memory modules. This direct thermal coupling enables extremely efficient heat removal whilst minimising temperature differentials between components and cooling systems.

Rear-door heat exchangers provide a retrofit-compatible cooling enhancement where liquid-cooled heat exchangers replace conventional rear doors on server racks, enabling heat removal at the rack level without requiring modifications to server equipment. Rear-door cooling provides substantial cooling capacity improvements whilst maintaining compatibility with existing server infrastructure.

Immersion cooling technologies submerge server equipment completely in dielectric fluids that provide both cooling and electrical insulation. Two-phase immersion cooling utilises fluid boiling to transfer heat, whilst single-phase immersion relies on fluid circulation and external heat exchangers. Immersion cooling provides exceptional cooling performance whilst eliminating airflow requirements entirely.

In-row cooling units incorporate liquid-to-air heat exchangers positioned within server rows, providing localised cooling that reduces the temperature differentials and airflow distances that compromise efficiency in traditional room-level cooling. In-row liquid cooling enhances cooling precision whilst improving energy efficiency.

Overhead liquid cooling distribution provides coolant delivery through ceiling-mounted pipe networks that minimise floor space consumption whilst simplifying installation and maintenance access. Overhead distribution must address leak detection, emergency drainage, and seismic restraint requirements that protect equipment from potential coolant release.

Hybrid cooling approaches combine liquid cooling for high-density equipment with air cooling for lower-density systems, optimising infrastructure investment whilst providing flexibility for diverse equipment requirements. Hybrid implementations require careful integration to maintain consistent environmental conditions.

Coolant Selection and Fluid Management Systems

Coolant selection represents a critical design decision that influences thermal performance, equipment compatibility, environmental safety, and regulatory compliance throughout facility lifecycle. Coolant properties including thermal capacity, electrical conductivity, chemical stability, and environmental impact determine system performance and operational requirements.

Water-based coolants with corrosion inhibitors and freeze protection additives provide excellent thermal performance whilst maintaining relatively low cost and environmental compatibility. Water-based systems require careful attention to fluid quality, corrosion prevention, and biological growth control that influence long-term system reliability.

Glycol-water mixtures provide freeze protection for systems that may experience low ambient temperatures whilst maintaining good thermal performance. Glycol concentrations must balance freeze protection requirements against thermal performance impacts and viscosity considerations that influence pumping energy.

Dielectric fluids enable direct contact with electronic components whilst providing electrical insulation that prevents short circuits. Dielectric coolants include hydrofluoroethers, synthetic esters, and engineered fluids specifically formulated for electronics cooling applications. Dielectric fluid selection must address environmental regulations, thermal properties, and material compatibility.

Refrigerants utilised in two-phase cooling systems provide exceptional thermal performance through evaporative cooling mechanisms. Refrigerant selection must address environmental regulations including global warming potential limitations, ozone depletion restrictions, and safety classifications that influence system design and operational requirements.

Fluid quality management systems monitor coolant condition, maintain chemical balance, and prevent contamination that could compromise thermal performance or equipment integrity. Quality management includes filtration, chemical analysis, and treatment systems that preserve coolant properties throughout operational lifecycle.

Fluid handling procedures address filling, draining, and maintenance activities that require careful contamination prevention, spill containment, and disposal planning. Proper fluid handling prevents equipment damage whilst ensuring environmental protection and personnel safety.

System Design and Integration Requirements

Liquid cooling system design encompasses thermal analysis, hydraulic design, and integration planning that ensure adequate cooling capacity whilst maintaining reliability standards required for mission-critical applications. Comprehensive design addresses both steady-state performance and transient response characteristics.

Heat load analysis determines cooling requirements based on equipment specifications, diversity factors, and growth projections that influence system capacity. Accurate load analysis prevents both undersizing that compromises performance and oversizing that wastes capital investment and operational energy.

Hydraulic design ensures adequate coolant flow rates, pressure drops, and pump sizing that deliver required cooling whilst minimising energy consumption. Hydraulic analysis includes pipe sizing, valve selection, and pump specification that optimise system performance.

Redundancy architecture addresses reliability requirements through N+1 or 2N configurations that maintain cooling during equipment failures or maintenance activities. Redundancy design must consider failure modes, automatic switchover mechanisms, and manual intervention requirements.

Temperature control systems maintain precise coolant temperatures that optimise thermal performance whilst preventing condensation formation. Control systems include temperature sensors, control valves, and automation logic that maintain stable operating conditions.

Leak detection systems provide comprehensive monitoring that identifies coolant release rapidly enough to enable emergency response before equipment damage occurs. Detection systems include spot sensors, continuous cable sensors, and environmental monitoring that provide multilayer protection.

Emergency response systems address coolant release scenarios through automatic shutdowns, drainage systems, and containment provisions that protect equipment and personnel. Emergency systems include automatic isolation valves, drainage provisions, and alarm systems that enable rapid response.

Installation Standards and Quality Assurance

Liquid cooling installation requires specialised expertise, precise fabrication, and comprehensive quality assurance that ensures system integrity whilst preventing the coolant release scenarios that could damage equipment or disrupt operations. Installation quality directly influences long-term system reliability and operational safety.

Pipe fabrication standards address material selection, joining methods, and pressure testing requirements that ensure system integrity. Piping systems require corrosion-resistant materials, leak-free connections, and comprehensive testing that verifies installation quality before commissioning.

Connection integrity verification ensures that all piping connections, component interfaces, and distribution fittings provide leak-free operation under operational pressures and temperature cycles. Connection testing includes hydrostatic pressure tests, leak detection, and visual inspection that confirms installation quality.

Seismic restraint requirements address earthquake protection through proper bracing, flexible connections, and anchorage systems that prevent pipe rupture during seismic events. Seismic design must meet applicable building codes whilst accommodating thermal expansion and system vibration.

Thermal insulation application prevents condensation formation, reduces heat gain, and improves energy efficiency through appropriate insulation materials and vapour barriers. Insulation installation must address thermal bridging, vapour sealing, and fire-resistance requirements.

Electrical isolation provisions ensure that coolant systems maintain electrical separation from electronic equipment whilst preventing galvanic corrosion between dissimilar metals. Isolation includes dielectric fittings, electrical bonding, and grounding systems that prevent electrical hazards.

Cleanliness protocols prevent contamination during installation through proper flushing, filtration, and cleanliness verification before system commissioning. Installation cleanliness directly influences long-term system reliability and equipment protection.

Regulatory Compliance and Safety Standards

Liquid cooling systems must comply with building codes, mechanical codes, and electrical safety standards that address coolant properties, system design, and installation requirements. Compliance requirements vary significantly based on coolant type, system design, and installation location within facilities.

Building code compliance addresses structural loading, fire protection, and mechanical system requirements applicable to liquid cooling installations. Code compliance includes load calculations, fire-resistance ratings, and system classification that influence design and installation requirements.

Mechanical code requirements address piping materials, pressure testing, and system safety provisions including pressure relief, overpressure protection, and emergency shut-off systems. Mechanical codes provide minimum safety standards whilst allowing engineering judgment for specific applications.

Electrical code compliance ensures that liquid cooling systems maintain electrical safety through proper grounding, bonding, and separation from electrical equipment. Electrical requirements address both personnel safety and equipment protection from electrical hazards.

Environmental regulations address coolant selection, leak prevention, and disposal requirements that protect environmental resources. Environmental compliance includes refrigerant regulations, chemical handling requirements, and waste disposal protocols that ensure environmental protection.

Fire protection considerations address combustibility characteristics, suppression system compatibility, and emergency response requirements specific to coolant properties. Fire protection design must consider coolant behaviour during fire conditions whilst maintaining equipment protection.

Occupational safety standards address personnel exposure limits, handling procedures, and emergency response requirements that protect workers during installation, operation, and maintenance activities. Safety compliance includes exposure monitoring, personal protective equipment, and training requirements.

Monitoring Systems and Operational Management

Comprehensive monitoring systems provide real-time visibility into liquid cooling performance, early warning of potential problems, and data collection that supports both operational optimisation and predictive maintenance. Monitoring systems represent essential operational infrastructure for reliable liquid cooling operation.

Temperature monitoring throughout supply, return, and critical points provides comprehensive thermal performance visibility whilst enabling rapid detection of cooling degradation. Temperature monitoring includes redundant sensors, data logging, and alarm thresholds that ensure operational awareness.

Flow rate monitoring ensures adequate coolant circulation whilst detecting pump failures, valve malfunctions, or flow restrictions that could compromise cooling performance. Flow monitoring includes flow meters, low-flow alarms, and automatic responses that protect equipment.

Pressure monitoring throughout cooling systems detects leaks, pump failures, and system restrictions that affect performance or indicate potential failures. Pressure monitoring includes differential pressure measurement, absolute pressure tracking, and alarm conditions that enable proactive response.

Leak detection systems provide multilayer protection through spot sensors at potential leak locations, continuous cable sensors along pipe runs, and environmental monitoring that detects coolant presence. Leak detection enables rapid response before equipment damage occurs.

Fluid quality monitoring tracks coolant condition, contamination levels, and chemical balance that influence thermal performance and system longevity. Quality monitoring includes conductivity measurement, pH monitoring, and periodic laboratory analysis that guide maintenance activities.

Energy consumption monitoring quantifies cooling system efficiency whilst identifying optimisation opportunities and supporting sustainability reporting. Energy monitoring includes power measurement, efficiency calculation, and trending analysis that optimise operational costs.

Maintenance Requirements and Service Protocols

Liquid cooling systems require specialised maintenance procedures that differ substantially from air cooling maintenance whilst demanding greater attention to leak prevention, fluid quality, and system integrity. Comprehensive maintenance programs ensure long-term reliability whilst preventing the equipment failures that could disrupt mission-critical operations.

Preventive maintenance schedules address regular inspection, testing, and component replacement that maintains system reliability. Maintenance schedules include visual inspection, leak testing, fluid analysis, and component servicing at intervals determined by manufacturer recommendations and operational experience.

Fluid management procedures maintain coolant quality through filtration, treatment, and periodic replacement that preserves thermal properties whilst preventing system degradation. Fluid maintenance includes contamination removal, chemical balancing, and quality verification that extends system life.

Component inspection procedures examine pumps, heat exchangers, valves, and instrumentation for wear, leaks, or degradation that could affect performance or reliability. Regular inspection enables early problem detection whilst supporting predictive maintenance planning.

Seal and gasket replacement addresses wear components that prevent leaks whilst maintaining system integrity. Seal replacement schedules balance preventive replacement against operational disruption whilst preventing premature failures.

Filter replacement maintains fluid cleanliness whilst preventing the pressure drops that compromise flow rates and cooling performance. Filter maintenance includes pressure differential monitoring, scheduled replacement, and contamination analysis that guides system improvements.

Emergency response procedures address coolant release scenarios, equipment failures, and system malfunctions that require rapid response to prevent equipment damage or operational disruption. Emergency procedures include isolation protocols, drainage systems, and equipment protection that minimise incident impact.

Performance Optimisation and Efficiency Enhancement

Liquid cooling systems provide substantial opportunities for performance optimisation and efficiency improvement through control refinement, operating parameter adjustment, and system balance optimisation. Systematic optimisation reduces operational costs whilst improving thermal performance and system reliability.

Temperature optimisation balances cooling performance against energy consumption through supply temperature adjustment that maintains adequate cooling whilst minimising chiller energy and pump power. Temperature optimisation considers equipment requirements, ambient conditions, and efficiency characteristics.

Flow optimisation ensures adequate coolant circulation whilst minimising pumping energy through flow balancing, valve adjustment, and pump speed optimisation. Flow optimisation addresses both thermal performance and energy efficiency throughout operating ranges.

Control system tuning refines automatic responses, set-point relationships, and operational sequences that optimise performance whilst maintaining stability. Control tuning includes proportional-integral-derivative parameter adjustment, dead-band optimisation, and sequence refinement that improve operational efficiency.

Heat recovery integration captures waste heat from cooling systems for beneficial use including space heating, domestic hot water, or absorption cooling. Heat recovery improves overall facility efficiency whilst reducing environmental impact.

Free cooling utilisation exploits favourable ambient conditions to reduce mechanical cooling energy through economiser operation, adiabatic cooling, or direct ambient cooling. Free cooling opportunities vary seasonally and geographically but provide substantial efficiency benefits when available.

Monitoring and analytics enable continuous performance assessment, trend analysis, and optimisation opportunity identification through comprehensive data collection and analysis. Advanced analytics support both operational optimisation and strategic planning for system improvements.

Emerging Technologies and Future Developments

Two-phase cooling technologies provide exceptional thermal performance through direct evaporative cooling of electronic components, enabling even higher power densities whilst reducing temperature differentials. Two-phase cooling represents an emerging technology with increasing deployment for extreme density applications.

Advanced dielectric fluids with improved thermal properties, reduced environmental impact, and enhanced safety characteristics continue to emerge, expanding immersion cooling applications and improving performance characteristics. Fluid development addresses global warming potential, biodegradability, and thermal performance.

Micro-channel heat exchangers provide extremely high heat transfer coefficients in compact geometries, enabling more efficient cooling whilst reducing coolant volumes and system footprints. Micro-channel technology benefits both direct-to-chip cooling and heat rejection systems.

Intelligent control systems incorporating machine learning and predictive algorithms optimise cooling performance dynamically whilst anticipating operational requirements and preventing problems before they affect performance. Advanced controls improve both efficiency and reliability.

Modular cooling solutions provide scalable deployment that matches cooling capacity to actual requirements whilst supporting rapid deployment and operational flexibility. Modular approaches reduce initial investment whilst providing expansion capability.

Refrigerant innovations address environmental regulations through low-global-warming-potential alternatives that maintain performance whilst reducing environmental impact. Refrigerant development continues to address both performance requirements and environmental sustainability.

The Integrated Approach: Delivering Liquid Cooling Excellence Through Partnership

Our partnership with Qcloud enables AuditCo to deliver comprehensive liquid cooling design, installation, and compliance services that address the emerging requirements of high-density computing infrastructure whilst ensuring regulatory compliance and operational reliability. This collaboration combines our established expertise in compliance verification and quality assurance with Qcloud’s advanced cooling technology expertise.

The integrated approach encompasses comprehensive design development, quality installation oversight, and compliance verification that ensures liquid cooling systems deliver required performance whilst maintaining safety standards and regulatory requirements. This methodology addresses both technical performance and compliance complexity.

Design services provide comprehensive engineering that addresses thermal requirements, hydraulic design, and integration planning whilst ensuring compliance with applicable codes and standards. Design services include load analysis, system selection, and detail engineering that optimise performance and reliability.

Installation oversight ensures that liquid cooling systems are installed according to design specifications whilst maintaining quality standards and safety requirements. Installation services include quality inspection, testing verification, and commissioning support that ensure system readiness.

Compliance services verify that liquid cooling installations meet building codes, mechanical standards, and safety requirements throughout design, installation, and operation. Compliance services include code analysis, inspection coordination, and approval documentation that ensure regulatory acceptance.

Testing and commissioning services provide comprehensive verification of system performance, safety features, and operational readiness before facility operation. Commissioning services include functional testing, performance verification, and operational training that ensure successful deployment.

Operational support services provide ongoing assistance with performance optimisation, maintenance planning and troubleshooting that maximises system benefits throughout operational lifecycle. Support services include performance monitoring, optimisation consulting, and technical assistance that ensure long-term success.

Training services ensure that operations teams receive comprehensive preparation for managing liquid cooling systems whilst maintaining safety awareness and operational excellence. Training includes system operation, maintenance procedures, and emergency response that support reliable operation.

Advanced Cooling for Future Computing Demands

Liquid cooling systems represent essential infrastructure for supporting the computational density requirements that artificial, intelligence, high-performance computing, and advanced graphics processing demand whilst providing energy efficiency benefits that improve operational economics and environmental sustainability. Comprehensive design, quality installation, and regulatory compliance ensure that liquid cooling systems deliver required performance whilst maintaining operational safety.

Our partnership with Qcloud enables AuditCo to deliver the comprehensive liquid cooling services that organisations require for successful deployment of advanced cooling technologies whilst ensuring regulatory compliance and operational reliability. By combining technical expertise with systematic compliance management, we help clients achieve cooling excellence that supports both current requirements and future computational growth.

The investment in professional liquid cooling design and implementation services represents essential preparation for high-density computing infrastructure that supports contemporary operational demands. For organisations seeking to deploy advanced cooling technologies capable of supporting extreme computational densities whilst maintaining operational efficiency, comprehensive design and compliance services provide the foundation for achieving cooling excellence.

AuditCo provides comprehensive audit, inspection, and compliance services for digital infrastructure projects worldwide. Our partnership with Qcloud enables integrated design-build-comply solutions that deliver liquid cooling excellence whilst ensuring regulatory compliance and operational reliability for high-density computing infrastructure. For more information about our liquid cooling services, please contact info@auditco.com.au