Factory Production Control: Ensuring Quality Before Installation

Factory Production Control: Ensuring Quality Before Installation

Supply Chain Compliance Management Strategies for Mission-Critical Infrastructure

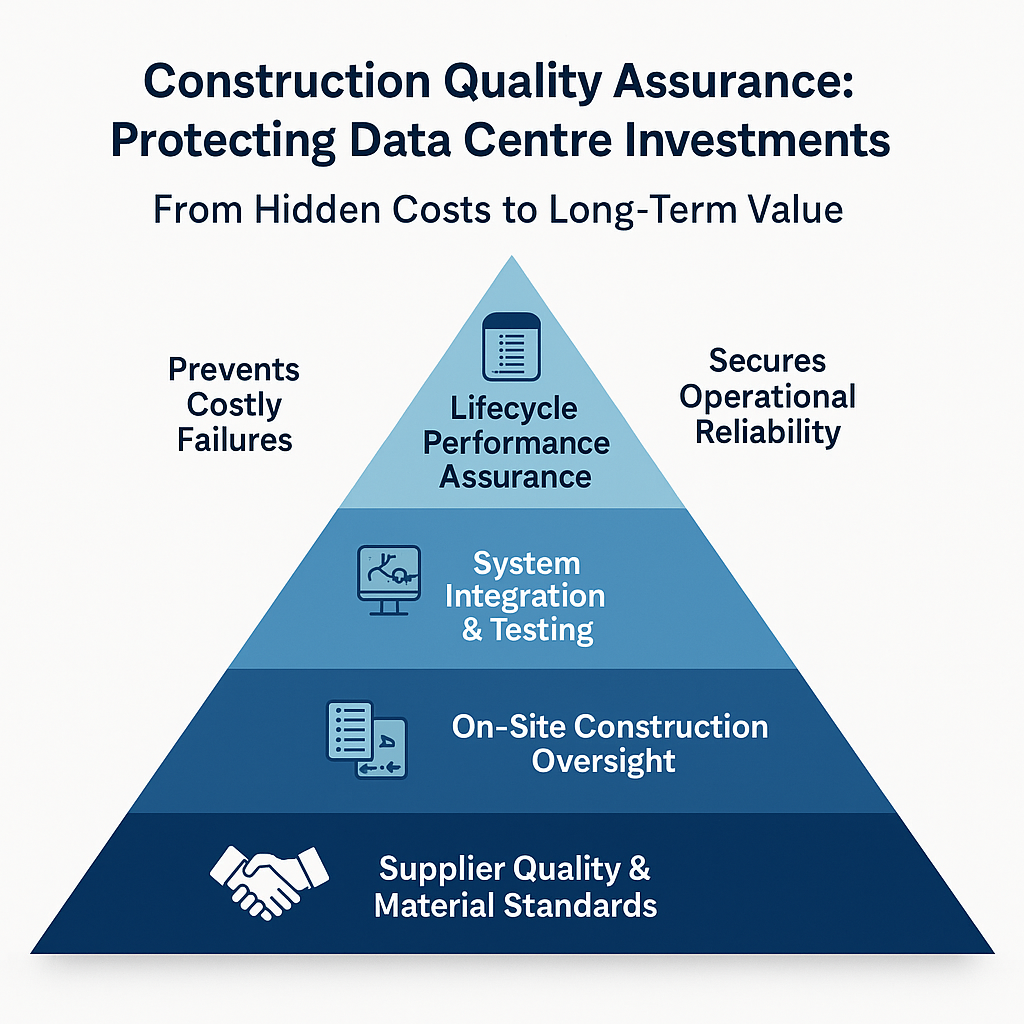

The complexity of modern hyperscale data centre infrastructure demands manufacturing quality that extends far beyond traditional construction industry standards. Critical power systems, sophisticated cooling equipment, and precision electrical components require factory production control methodologies that ensure consistent quality, regulatory compliance, and performance reliability before equipment leaves manufacturing facilities.

Traditional approaches to quality management—inspecting equipment after delivery and attempting remediation during construction phases—create unacceptable risks for mission-critical facilities where equipment failure can result in substantial revenue losses and reputational damage. Modern hyperscale development demands proactive factory production control that verifies quality, performance, and compliance throughout manufacturing processes.

At AuditCo, our partnership with Qcloud has enhanced our capability to deliver comprehensive factory production control services that ensure supply chain compliance across the complex ecosystem of hyperscale infrastructure manufacturing. This collaboration combines our established expertise in quality assurance and compliance verification with Qcloud’s understanding of hyperscale equipment requirements and manufacturing standards.

The Strategic Foundation of Manufacturing Quality Assurance

Factory production control begins with comprehensive supplier qualification processes that evaluate manufacturing capabilities, quality management systems, and compliance frameworks before procurement decisions are finalised. This proactive approach ensures that selected suppliers possess the technical capabilities, quality systems, and regulatory compliance required for hyperscale equipment manufacturing.

ISO 9001 quality management system certification represents the baseline requirement for hyperscale equipment suppliers, providing assurance that manufacturing processes incorporate systematic quality control, continuous improvement, and customer satisfaction focus. However, hyperscale requirements often demand quality management capabilities that exceed baseline ISO 9001 requirements.

Manufacturing capability assessment evaluates production equipment, process control systems, and technical expertise to ensure that suppliers can deliver the precision, consistency, and reliability required for mission-critical applications. This assessment includes evaluation of manufacturing equipment calibration, process documentation, and operator competency that influence product quality.

Quality control system verification ensures that suppliers maintain comprehensive inspection, testing, and documentation procedures throughout manufacturing processes. Effective quality control systems provide objective evidence of conformance to specifications whilst identifying potential non-conformances before products are shipped.

Regulatory compliance verification ensures that manufacturing processes meet applicable standards, certifications, and regulatory requirements that influence product acceptance and installation approval. This includes verification of product certifications, manufacturing process approvals, and regulatory compliance documentation.

Supply chain transparency enables traceability of materials, components, and manufacturing processes that influence product quality and regulatory compliance. Comprehensive supply chain visibility supports both quality assurance and compliance verification throughout the manufacturing process.

Material Control and Component Verification

Raw material qualification represents a critical foundation for manufacturing quality, where material properties, certifications, and traceability directly influence finished product performance. Comprehensive material qualification includes chemical composition verification, mechanical property testing, and certification documentation that ensures materials meet specification requirements.

Incoming inspection procedures verify that raw materials and purchased components conform to specifications before entering manufacturing processes. Effective incoming inspection includes dimensional verification, material property testing, and certification document review that prevents non-conforming materials from compromising finished product quality.

Material traceability systems enable tracking of raw materials and components throughout manufacturing processes, providing the documentation required for quality investigations and regulatory compliance. Comprehensive traceability systems support both quality assurance and compliance verification requirements.

Component qualification procedures ensure that purchased components meet performance, quality, and reliability requirements before incorporation into finished products. This includes vendor qualification, incoming inspection, and performance verification that confirms component suitability for hyperscale applications.

Material handling procedures prevent damage, contamination, or degradation that could compromise product quality during manufacturing processes. Effective material handling includes environmental controls, packaging protection, and handling procedures that maintain material integrity throughout production.

Inventory management systems ensure that materials and components are stored, tracked, and utilised in accordance with specifications and quality requirements. Comprehensive inventory management includes environmental controls, stock rotation procedures, and expiration date management that maintain material quality.

Manufacturing Process Control and Verification

Process control systems ensure that manufacturing operations consistently produce products that meet specifications whilst identifying process variations that could compromise quality. Effective process control includes parameter monitoring, statistical process control, and corrective action procedures that maintain manufacturing consistency.

Calibration management systems ensure that manufacturing equipment, measuring instruments, and test equipment maintain accuracy throughout production processes. Comprehensive calibration management includes calibration schedules, uncertainty analysis, and traceability to national standards that support measurement reliability.

Work instruction documentation provides detailed procedures that ensure consistent manufacturing processes whilst supporting operator training and competency development. Effective work instructions include step-by-step procedures, quality checkpoints, and acceptance criteria that guide manufacturing operations.

In-process inspection procedures verify product quality throughout manufacturing processes, identifying potential non-conformances before significant manufacturing resources are invested. Strategic in-process inspection includes dimensional verification, functional testing, and visual inspection that confirms conformance to specifications.

Manufacturing environment control ensures that production conditions maintain the cleanliness, temperature, humidity, and other environmental parameters required for quality manufacturing. Environmental control is particularly important for electronic components, precision assemblies, and sensitive materials that require controlled conditions.

Process capability studies demonstrate that manufacturing processes can consistently produce products within specification limits whilst providing data for process optimisation and quality improvement. Comprehensive capability studies include statistical analysis, measurement system analysis, and process variation assessment.

Testing and Performance Verification

Factory acceptance testing provides comprehensive verification of equipment performance, functionality, and compliance before shipment to project sites. Effective factory acceptance testing includes performance testing, safety verification, and compliance confirmation that ensures equipment readiness for installation.

Performance testing procedures verify that equipment meets specification requirements under various operating conditions whilst providing documentation for commissioning and operational planning. Comprehensive performance testing includes efficiency verification, capacity confirmation, and operational parameter validation.

Safety testing verification ensures that equipment incorporates appropriate safety systems, protection devices, and fail-safe mechanisms that protect personnel and equipment during installation and operation. Safety testing includes protective device verification, emergency shutdown testing, and safety system integration confirmation.

Environmental testing confirms that equipment can operate reliably under the environmental conditions expected during transportation, storage, and operation. Environmental testing may include temperature cycling, humidity exposure, vibration testing, and other environmental stresses that equipment may encounter.

Electromagnetic compatibility testing ensures that equipment operates without electromagnetic interference whilst avoiding interference with other systems and equipment. EMC testing is particularly important for electronic systems and power equipment that operate in data centre environments with multiple electromagnetic sources.

Compliance testing verification confirms that equipment meets applicable standards, regulations, and certification requirements that influence installation approval and operational compliance. Compliance testing includes safety standard verification, performance standard confirmation, and regulatory requirement validation.

Documentation and Certification Management

Manufacturing documentation systems provide comprehensive records of materials, processes, testing, and compliance verification that support both quality assurance and regulatory compliance. Effective documentation systems include material certificates, test reports, inspection records, and compliance documentation.

Certificate of compliance documentation confirms that manufactured equipment meets specification requirements, regulatory standards, and quality system requirements. Comprehensive compliance certificates include material certifications, test results, inspection records, and quality system verification.

Test report documentation provides detailed records of performance testing, safety verification, and compliance confirmation that support commissioning and operational planning. Effective test reports include test procedures, acceptance criteria, actual results, and non-conformance resolution.

Quality assurance documentation demonstrates that manufacturing processes incorporate systematic quality control, continuous improvement, and compliance verification throughout production. Quality documentation includes quality plans, inspection records, corrective action reports, and management review records.

Traceability documentation enables tracking of materials, components, and manufacturing processes throughout product lifecycle, supporting quality investigations and regulatory compliance requirements. Comprehensive traceability includes material certificates, process records, inspection documentation, and shipping records.

Warranty documentation provides assurance of equipment performance, reliability, and manufacturer support throughout specified warranty periods. Comprehensive warranty documentation includes performance guarantees, maintenance requirements, and warranty claim procedures.

Supply Chain Risk Management and Continuity Planning

Supplier risk assessment identifies potential vulnerabilities in manufacturing capabilities, quality systems, and business continuity that could affect product delivery or quality. Comprehensive risk assessment includes financial stability evaluation, manufacturing capability assessment, and quality system verification.

Supply chain diversification strategies reduce dependency on single suppliers whilst maintaining quality standards and delivery reliability. Effective diversification includes qualified alternate suppliers, multi-source strategies, and supplier performance monitoring that ensure supply chain resilience.

Business continuity planning addresses potential disruptions to manufacturing operations, supply chain logistics, and quality assurance systems that could affect project delivery. Comprehensive continuity planning includes risk mitigation strategies, alternate supplier activation, and emergency response procedures.

Quality incident management procedures ensure rapid response to quality issues, non-conformances, and customer concerns that require investigation and resolution. Effective incident management includes root cause analysis, corrective action implementation, and preventive action development.

Supplier performance monitoring systems track quality performance, delivery reliability, and compliance adherence throughout ongoing supplier relationships. Comprehensive performance monitoring includes quality metrics, delivery performance, and compliance verification that support supplier management decisions.

Supply chain audit programs provide independent verification of supplier quality systems, manufacturing capabilities, and compliance frameworks. Regular supply chain audits ensure ongoing supplier qualification whilst identifying improvement opportunities and compliance gaps.

Technology Integration and Digital Quality Management

Digital quality management systems enable real-time monitoring of manufacturing processes, automated data collection, and comprehensive quality analytics that support proactive quality management. Digital systems provide enhanced visibility, improved decision-making, and reduced manual intervention requirements.

Manufacturing execution systems integrate quality control with production planning, inventory management, and scheduling systems that optimise manufacturing efficiency whilst maintaining quality standards. Integrated systems provide comprehensive visibility and coordinated control of manufacturing operations.

Statistical process control systems provide real-time monitoring of manufacturing processes, automatic detection of process variations, and predictive analysis that prevents quality issues before they occur. Advanced statistical control enables proactive quality management and process optimisation.

Quality management software systems provide comprehensive documentation, workflow management, and reporting capabilities that streamline quality assurance whilst ensuring compliance verification. Integrated quality management systems support both operational efficiency and regulatory compliance requirements.

Remote monitoring capabilities enable customer visibility into manufacturing processes, quality verification, and delivery preparation that support project planning and quality assurance. Remote monitoring provides transparency and early warning of potential issues that could affect delivery schedules.

Blockchain technology applications enable immutable documentation of manufacturing processes, quality verification, and supply chain traceability that support both quality assurance and regulatory compliance. Blockchain applications provide enhanced security and verification capabilities for critical quality documentation.

International Standards and Regulatory Compliance

ISO quality management standards provide the framework for systematic quality control, continuous improvement, and customer satisfaction focus that supports hyperscale equipment manufacturing. Compliance with relevant ISO standards demonstrates manufacturing capability and quality system maturity.

Product certification requirements vary significantly across international markets, requiring understanding of applicable standards, testing requirements, and certification procedures that influence market acceptance. Comprehensive certification management ensures product compliance across target markets.

Environmental compliance requirements increasingly influence manufacturing processes, material selection, and waste management procedures that affect both regulatory compliance and corporate sustainability objectives. Environmental compliance demonstrates corporate responsibility whilst ensuring regulatory adherence.

Safety standard compliance ensures that manufacturing processes and finished products meet applicable safety requirements that protect personnel during manufacturing, installation, and operation. Safety compliance includes both process safety and product safety requirements.

Quality system accreditation provides independent verification of manufacturing quality capabilities, regulatory compliance, and customer satisfaction focus. Accreditation demonstrates quality system maturity whilst providing customer assurance of manufacturing capability.

International trade compliance requirements affect documentation, certification, and shipping procedures that influence product delivery and regulatory acceptance. Trade compliance includes customs documentation, product certification, and regulatory approval requirements.

The Integrated Approach: Delivering Supply Chain Excellence Through Partnership

Our partnership with Qcloud enables AuditCo to deliver comprehensive factory production control services that ensure supply chain compliance across the complex ecosystem of hyperscale infrastructure manufacturing. This collaboration combines our established expertise in quality assurance and compliance verification with understanding of hyperscale equipment requirements and manufacturing standards.

The integrated approach begins with supplier qualification and continues throughout manufacturing processes, providing comprehensive verification of quality, performance, and compliance before equipment shipment. This methodology ensures that equipment meets specification requirements whilst providing the documentation required for successful commissioning.

Quality assurance services include factory inspections, process audits, and performance verification that confirm manufacturing quality whilst identifying improvement opportunities. Our systematic approach to quality verification provides confidence in equipment performance whilst supporting continuous improvement initiatives.

Compliance verification services ensure that manufacturing processes and finished products meet applicable standards, regulations, and certification requirements across multiple international markets. Comprehensive compliance verification prevents delays and complications during installation and commissioning phases.

Supply chain risk management services identify potential vulnerabilities whilst developing mitigation strategies that ensure delivery reliability and quality consistency. Proactive risk management prevents supply chain disruptions whilst maintaining quality standards throughout project delivery.

Documentation and certification services provide comprehensive records of quality verification, compliance confirmation, and performance testing that support both installation planning and operational requirements. Systematic documentation ensures that equipment installations proceed smoothly whilst providing the records required for ongoing facility management.

Conclusion: Manufacturing Excellence for Mission-Critical Performance

Factory production control represents an essential foundation for successful hyperscale facility development, where equipment quality, performance, and reliability directly influence operational success throughout facility lifecycles. Comprehensive supply chain compliance management ensures that manufacturing quality meets the demanding requirements of mission-critical applications.

Our partnership with Qcloud enables AuditCo to deliver the comprehensive factory production control services that hyperscale operators require for confident equipment procurement and installation. By combining rigorous quality assurance with deep understanding of hyperscale requirements, we help clients achieve manufacturing excellence that supports both current projects and long-term operational success.

The investment in professional factory production control services represents essential preparation for reliable facility operations throughout equipment lifecycles. For hyperscale operators seeking to ensure that critical infrastructure meets the highest standards of quality, performance, and reliability, comprehensive supply chain compliance management provides the foundation for achieving these objectives.

AuditCo provides comprehensive audit, inspection, and compliance services for digital infrastructure projects worldwide. Our partnership with Qcloud enables integrated design-build-comply solutions that ensure factory production control and supply chain compliance for hyperscale infrastructure excellence. For more information about our factory production control services, please contact our team at info@auditco.com.au