The Evolution of White Space Engineering in Modern Data Centres

The Evolution of White Space Engineering in Modern Data Centres

Precision Engineering for Mission-Critical Performance

The white space within a data centre represents the culmination of months of planning, design, and construction effort. This carefully controlled environment houses the servers, storage systems, and networking equipment that power the digital economy, yet the engineering precision required to create optimal white space conditions remains poorly understood outside specialist circles.

Modern white space engineering extends far beyond traditional mechanical and electrical installation. The convergence of higher power densities, liquid cooling technologies, and stringent efficiency requirements has transformed white space design into a sophisticated discipline that demands deep understanding of thermal dynamics, power distribution, and environmental control systems.

At AuditCo, our partnership with Qcloud has strengthened our capability to deliver comprehensive white space engineering services that address the full spectrum of hyperscale requirements. This collaboration combines our rigorous approach to quality assurance and compliance verification with Qcloud’s specialist expertise in white space design, installation, and commissioning for hyperscale operators across emerging markets.

The Foundation of White Space Performance

White space engineering begins with understanding the fundamental requirements that distinguish data centre environments from conventional commercial spaces. The precision required for optimal server performance, the redundancy necessary for continuous operations, and the efficiency demanded by modern sustainability standards create design challenges that require specialist engineering expertise.

Environmental control within white space areas must maintain temperature and humidity parameters within extremely narrow tolerances. Server equipment operates optimally within specific environmental ranges, with deviations potentially causing performance degradation, increased failure rates, or complete system shutdowns. Modern white space design employs sophisticated computational fluid dynamics modelling to predict airflow patterns, identify potential hot spots, and optimise cooling distribution throughout the facility.

Power distribution within white space areas requires careful consideration of load balancing, redundancy requirements, and future expansion capabilities. Hyperscale facilities typically operate at power densities that would overwhelm conventional electrical systems, making specialised power distribution infrastructure essential for reliable operations. White space engineering includes detailed power analysis that ensures adequate capacity whilst maintaining the redundancy levels required for mission-critical operations.

The raised floor system that characterises most data centre white spaces serves multiple critical functions beyond cable management. Properly designed raised floor systems provide structured pathways for cooling air distribution, accommodate the substantial weight of server equipment, and enable flexible reconfiguration as operational requirements evolve. The engineering precision required for optimal raised floor performance includes load distribution analysis, airflow modelling, and accessibility planning that supports ongoing operational requirements.

Cable management within white space areas significantly influences both operational efficiency and future expansion capabilities. Modern data centres house thousands of power, data, and fibre optic cables that must be organised, protected, and accessible for maintenance activities. Comprehensive cable management design considers current requirements, future expansion scenarios, and maintenance accessibility whilst maintaining the clean, organised appearance that characterises professional data centre operations.

Advanced Cooling Technologies and Installation Precision

The evolution towards higher server power densities has driven fundamental changes in white space cooling technologies. Traditional air cooling systems, whilst still prevalent, increasingly operate alongside liquid cooling solutions that can handle the thermal loads generated by modern high-performance computing equipment.

Liquid cooling installation within white space areas requires exceptional precision to prevent the catastrophic failures that could result from cooling fluid leaks. Installation teams must demonstrate expertise in specialised coupling systems, leak detection technologies, and emergency containment procedures that protect sensitive electronic equipment. The integration of liquid cooling infrastructure with existing air cooling systems demands careful coordination to maintain environmental conditions throughout the installation process.

Direct-to-chip cooling systems represent the cutting edge of white space thermal management, delivering cooling directly to processors and memory modules that generate the highest thermal loads. These systems require precise installation tolerances, specialised maintenance procedures, and integration with facility-wide cooling infrastructure that maintains optimal performance whilst providing the redundancy required for continuous operations.

Immersion cooling technologies, where servers operate within dielectric fluids, represent perhaps the most significant evolution in white space engineering. These systems require completely different installation methodologies, environmental controls, and maintenance procedures compared to traditional air-cooled environments. Installation teams must understand fluid handling procedures, contamination prevention, and the unique safety requirements associated with immersion cooling operations.

The commissioning of advanced cooling systems within white space areas requires comprehensive testing procedures that verify performance under various load conditions. Thermal mapping, airflow verification, and system integration testing ensure that cooling systems deliver the precise environmental conditions required for optimal server performance whilst maintaining the efficiency levels demanded by modern sustainability requirements.

Power Infrastructure and Electrical Precision

White space power infrastructure represents one of the most critical aspects of data centre engineering, where installation precision directly influences operational reliability and safety. The power densities common in modern hyperscale facilities create electrical loads that require sophisticated distribution systems, comprehensive monitoring capabilities, and robust protection mechanisms.

Uninterruptible power supply systems within white space areas must provide seamless power conditioning whilst maintaining the compact footprint required for efficient space utilisation. Installation of UPS systems requires careful consideration of airflow requirements, maintenance accessibility, and integration with facility-wide power management systems. The precision required for optimal UPS performance includes detailed load analysis, battery management system integration, and comprehensive testing procedures that verify performance under various operating conditions.

Power distribution units within white space areas serve as the final link between facility power infrastructure and server equipment. Modern PDUs incorporate sophisticated monitoring capabilities, remote management features, and safety systems that protect both equipment and personnel. Installation requires precise positioning for optimal cable management, adequate cooling airflow, and accessibility for ongoing maintenance activities.

Electrical safety within white space areas demands rigorous installation procedures and comprehensive testing protocols. The combination of high electrical loads, sophisticated control systems, and dense equipment arrangements creates safety challenges that require specialist expertise. Installation teams must demonstrate competency in arc flash protection, electrical isolation procedures, and emergency response protocols that ensure personnel safety throughout the facility lifecycle.

Grounding and bonding systems within white space areas require exceptional precision to prevent electromagnetic interference whilst ensuring personnel safety. The complex interactions between power systems, cooling infrastructure, and sensitive electronic equipment create grounding challenges that require detailed analysis and precise installation procedures. Comprehensive grounding system testing verifies electrical continuity, resistance values, and isolation characteristics that ensure optimal system performance.

Installation Methodology and Quality Assurance

The installation of white space infrastructure requires systematic methodologies that ensure consistent quality whilst minimising disruption to ongoing operations. Modern hyperscale facilities often operate on compressed construction schedules that demand efficient installation procedures without compromising the precision required for optimal performance.

Modular installation approaches enable parallel work streams that accelerate project delivery whilst maintaining quality standards. Pre-fabricated power distribution systems, cooling infrastructure modules, and cable management assemblies can be manufactured off-site to precise specifications, then installed and commissioned using systematic procedures that ensure consistent performance across multiple installation areas.

Quality control during white space installation requires comprehensive inspection procedures that verify compliance with design specifications, industry standards, and operational requirements. Installation teams must maintain detailed documentation that demonstrates compliance with electrical codes, mechanical specifications, and safety requirements throughout the installation process.

Testing and commissioning procedures for white space systems require systematic approaches that verify individual component performance and integrated system operation. Comprehensive testing includes power system verification, cooling performance validation, monitoring system calibration, and safety system functionality testing that ensures optimal performance before equipment installation begins.

Environmental commissioning represents a critical phase of white space installation where thermal performance, airflow distribution, and humidity control systems undergo comprehensive testing. Environmental commissioning includes mapping of temperature and humidity conditions throughout the white space area, verification of cooling system capacity under various load conditions, and validation of control system response to changing environmental requirements.

Integration with Facility Infrastructure

White space engineering cannot be considered in isolation from broader facility infrastructure systems. The successful integration of white space systems with grey space infrastructure, building management systems, and external utility connections requires comprehensive coordination throughout the design and installation process.

Mechanical system integration ensures that white space cooling requirements align with facility-wide heating, ventilation, and air conditioning systems. This integration includes coordination of airflow requirements, heat rejection systems, and control system interfaces that maintain optimal white space conditions whilst optimising facility-wide energy efficiency.

Electrical system integration encompasses the connection between white space power distribution and facility electrical infrastructure. This integration requires careful load balancing, protection system coordination, and monitoring system interfaces that ensure reliable power delivery whilst maintaining the safety and efficiency standards required for optimal facility performance.

Building management system integration enables centralised monitoring and control of white space environmental conditions, power consumption, and safety systems. Integration requires careful consideration of communication protocols, data security requirements, and operational procedures that enable effective facility management whilst maintaining the reliability required for mission-critical operations.

Fire protection system integration within white space areas requires specialised detection and suppression systems that protect sensitive electronic equipment whilst ensuring personnel safety. Integration includes coordination with facility-wide fire alarm systems, emergency response procedures, and suppression agent delivery systems that provide effective protection without causing equipment damage.

Future-Proofing White Space Infrastructure

The rapid evolution of server technologies, cooling requirements, and efficiency standards demands white space engineering approaches that accommodate future requirements whilst optimising current performance. Future-proofing strategies require careful analysis of technology trends, capacity planning, and infrastructure flexibility that enable cost-effective adaptation to changing requirements.

Modular infrastructure design enables incremental capacity expansion without disrupting existing operations. Modular approaches include expandable power distribution systems, scalable cooling infrastructure, and flexible cable management solutions that accommodate growth whilst maintaining optimal performance characteristics.

Cooling system flexibility enables adaptation to evolving thermal management requirements as server technologies advance. Flexible cooling design includes provision for liquid cooling integration, variable airflow requirements, and alternative cooling technologies that may become optimal as efficiency requirements evolve.

Power infrastructure scalability ensures that white space areas can accommodate increasing power densities without requiring fundamental infrastructure modifications. Scalable power design includes adequate electrical service capacity, expandable distribution systems, and monitoring capabilities that support growth whilst maintaining safety and efficiency standards.

Technology refresh planning enables systematic equipment updates that maintain optimal performance whilst minimising operational disruption. Refresh planning includes consideration of equipment lifecycle management, installation procedures for new technologies, and integration strategies that ensure seamless transitions between technology generations.

The Integrated Approach: Delivering Excellence Through Partnership

Our partnership with Qcloud enables AuditCo to deliver comprehensive white space engineering services that address the full spectrum of hyperscale requirements. This collaboration combines our established expertise in quality assurance, compliance verification, and risk management with Qcloud’s deep understanding of white space design and installation requirements.

The integrated approach ensures seamless coordination between design, installation, and commissioning activities that optimise project delivery whilst maintaining the quality standards required for hyperscale operations. This coordination eliminates the potential gaps and delays that can occur when multiple contractors work independently, delivering consistent quality and compressed project timelines.

Quality assurance throughout the white space installation process benefits from our systematic approach to inspection, testing, and documentation that ensures compliance with design specifications and industry standards. Our quality assurance methodologies provide the verification and documentation required for successful commissioning whilst establishing the baseline for ongoing operational management.

Regional expertise enables effective project delivery across diverse market conditions whilst maintaining consistent quality standards. Our combined presence across multiple regions ensures that white space engineering projects benefit from local knowledge and established supplier relationships whilst applying proven methodologies developed through extensive hyperscale experience.

The transition from installation to operations benefits from continuity of expertise that understands design intent, installation details, and performance characteristics. This continuity ensures that operational teams receive comprehensive documentation, training, and support that enables optimal facility performance throughout the operational lifecycle.

Precision Engineering for Digital Infrastructure Excellence

White space engineering represents the culmination of sophisticated design, precise installation, and comprehensive commissioning activities that create the optimal environment for mission-critical digital infrastructure. The evolution towards higher power densities, advanced cooling technologies, and stringent efficiency requirements demands specialist expertise that addresses both current requirements and future adaptability.

Our partnership with Qcloud enables AuditCo to deliver the comprehensive white space engineering services that hyperscale operators require for successful facility development. By combining rigorous quality assurance with deep technical expertise, we help clients achieve the precision, reliability, and efficiency that characterise world-class data centre operations.

The investment in professional white space engineering services represents essential preparation for decades of reliable facility performance. For hyperscale operators seeking to establish facilities that deliver optimal performance, maintain operational reliability, and adapt to evolving requirements, comprehensive white space engineering provides the technical foundation for achieving these objectives.

AuditCo provides comprehensive audit, inspection, and compliance services for digital infrastructure projects worldwide. Our partnership with Qcloud enables integrated design-build-comply solutions that deliver the precision engineering required for hyperscale white space excellence. For more information about our white space engineering services, please contact our team at info@auditco.com.au

The Evolution of White Space Engineering in Modern Data Centres

The Evolution of White Space Engineering in Modern Data Centres

Related Posts

Project Close-out and Handover: Ensuring Seamless Transitions

Documentation, Warranties, and Knowledge Transfer for Mission-Critical Infrastructure The transition from construction completion to operational…

Sustainable Data Centre Design: Environmental Compliance and Green Energy

Integrating Environmental Responsibility with Mission-Critical Performance The accelerating growth of digital infrastructure has intensified scrutiny…

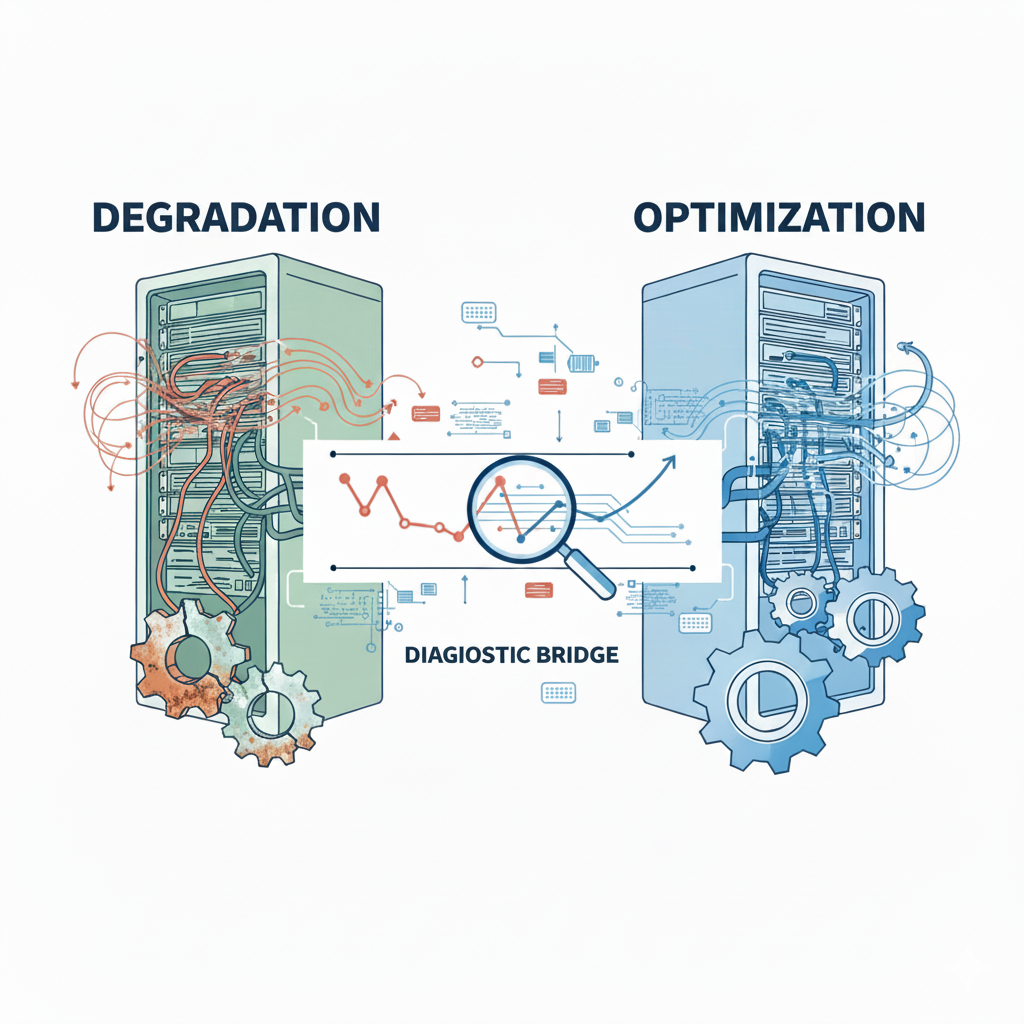

Performance Loss Testing: Identifying and Resolving Inefficiencies

Diagnostic Techniques and Optimisation Strategies for Mission-Critical Infrastructure The operational efficiency of data centre infrastructure…